Tungsten Alloy Counterweights: Tungsten Alloy Golf Club Counterweight: A golf club counterweight apparatus for selectively modifying the swing weight of a golf club having a shaft with a handle end and a he...

Hanns CEO/Chinatungten.com

Everything interesting about Tungsten Mine, Ore,Powder,Carbide and Alloy from the professional tungsten manufacturer

2012/04/05

2012/04/04

The New Weapon of Trading: Tungsten and/or Rare Earth of China?

The New Weapon: Tungsten and/or Rare Earth of China?

China has 65% of the world’s tungsten ore reserves, and accounted for about 85% of the global total tungsten output in 2010. As of 2010, China’s tungsten metal reserves were only 1900 thousand tons, which can merely be utilized for 20 years at the current rate of depletion. In order to promote reasonable exploration and utilization, tungsten was classified among the protected resources in China in 1991, and policies on limitation of exploration and exportation have been implemented from then on.

It is reported that China will cut down the export of tungsten raw materials because of the reason of enviroment protection in the future, then more and more international buyer and end user have to buy the tungsten sintered products from China's manufacuturers.

But if the buyer from military, from army, dose it may let China know how are these tungsten parts should be used? and when these tungsten may be shotted to China?

There's a real problem but not the materials itself, but the uses or application the materials, is that right? I don't know.

Hanns CEO/Chinatungten.com

China has 65% of the world’s tungsten ore reserves, and accounted for about 85% of the global total tungsten output in 2010. As of 2010, China’s tungsten metal reserves were only 1900 thousand tons, which can merely be utilized for 20 years at the current rate of depletion. In order to promote reasonable exploration and utilization, tungsten was classified among the protected resources in China in 1991, and policies on limitation of exploration and exportation have been implemented from then on.

Output and Exploitation Quota of Tungsten Concentrate (WO3, 65%) by Region in China, 2009-2010 (Ton)

Source: www.ctia.com.cn

Source: www.ctia.com.cn

It is reported that China will cut down the export of tungsten raw materials because of the reason of enviroment protection in the future, then more and more international buyer and end user have to buy the tungsten sintered products from China's manufacuturers.

But if the buyer from military, from army, dose it may let China know how are these tungsten parts should be used? and when these tungsten may be shotted to China?

There's a real problem but not the materials itself, but the uses or application the materials, is that right? I don't know.

Hanns CEO/Chinatungten.com

Yes, Tungsten Will be the Next Hot Rock!

Yes, Tungsten Will be the Next Hot Rock!

With demand for the metal on the rise, are investors like Berkshire Hathaway starting a "tungsten rush?"

With demand for the metal on the rise, are investors like Berkshire Hathaway starting a "tungsten rush?"

By Alex Konrad, reporter A chunk of ore with tungsten

A chunk of ore with tungsten

FORTUNE -- Tungsten, one of the hardest metals in the world and used for everything from drill bits to light bulbs to touch screens, is suddenly hot. Much of the increased demand is coming from China, which just happens to hold the world's biggest reserves. The country is hoarding mineral resources by reducing exports, according to mining strategist Christopher Ecclestone of Hallgarten & Company, as it produces more of its own precision tools using the metal. "China wants to keep more of the good stuff for itself," he says.

With the Chinese tightening their grip and a general uptick in demand, prices have soared to about $20 a pound, double from a few years ago. That has the relatively small number of tungsten miners, such as Malaga and Woulfe Mining, ramping up activity. Malaga is currently sending one container, which is about 28,000 pounds, of tungsten per week from its Pasto Bueno mine in Peru, according to CEO Pierre Monet. To meet the pressure for more material, he says the mine would have to up its production to five containers per day.

Other mining companies such as Woulfe are capitalizing upon mines that shut down in past years when prices were a lot lower. In 2009, Woulfe acquired a one-time leading tungsten producer, South Korea's Sangdong mine, years after it had closed in 1992. Now the company is in a race to bring Sangdong back online while prices stay high. Woulfe hopes to have the mine in production by the first quarter of next year, says CEO Brian Wesson. But the company, like the rest of its sector, has been in a fight to get the capital it needs to fund the project.

Though tungsten use is spread across a wide range of industries, the quantities involved are still relatively small. There's been little historical interest in the U.S., and few mining analysts cover the material. (Malaga and Woulfe are both based in Canada.) According to Ecclestone at Hallgarten, the long lag time with mines from investment to production has kept investment interest in them relatively muted and their valuations low.

But that could change if executives are right in predicting that tungsten prices stay at high levels for the long haul. The U.S. is paying more attention to strategic metals and recently sued the Chinese government for its export restrictions of "rare earth" minerals, And now Warren Buffett is getting in on the act.

IMC Group, a subsidiary of Buffett's Berkshire Hathaway (BRKA) that holds a diverse portfolio of metalworking companies, recently invested $70 million in Woulfe's South Korean tungsten operations. Half that money goes to the mine itself, with the rest helping to finance a nearby plant for processing the raw material, Woulfe CEO Wesson says. The processed tungsten will then be used by units within IMC.

Mining for a partner

The historical model has been for a mining company to have one project in a given rare metal, with diversification coming from other mines of different minerals. Woulfe, for example, also owns a gold mine, the Maguk project, in South Korea. But Ecclestone says he would not be surprised to see consolidation among tungsten producers. "There are 15 players in the space each with one project, and there should be seven with two projects each." Malaga CEO Monet also notes that there is a limited pool of experienced mining experts capable of starting a new mine from scratch.

Any merger and acquisition activity, however, returns to the question of capital, and the industry can only hope that Berkshire Hathaway proves ahead of the curve in opening up funding. The success of the venture, however, will ultimately depend on the price of tungsten in the months after Sangdong goes operational. Ecclestone says his analysis shows little reason to believe prices will "go bad" anytime soon. But China poses potential headaches for Woulfe and IMC if it tries to manipulate the price.

"As a competitor to China, you're in the cage with the 800-pound gorilla," Ecclestone warns. But it's a cage match that Berkshire Hathaway has bet it can win. Tungsten futures, anyone?

A shorter version of this story appeared in the April 9, 2012 issue of Fortune.

Posted in: Berkshire Hathaway, metals, mines, mining, tungsten, Warren Buffett

Hanns CEO/Chinatungten.com

With demand for the metal on the rise, are investors like Berkshire Hathaway starting a "tungsten rush?"

With demand for the metal on the rise, are investors like Berkshire Hathaway starting a "tungsten rush?"By Alex Konrad, reporter A chunk of ore with tungsten

A chunk of ore with tungsten

FORTUNE -- Tungsten, one of the hardest metals in the world and used for everything from drill bits to light bulbs to touch screens, is suddenly hot. Much of the increased demand is coming from China, which just happens to hold the world's biggest reserves. The country is hoarding mineral resources by reducing exports, according to mining strategist Christopher Ecclestone of Hallgarten & Company, as it produces more of its own precision tools using the metal. "China wants to keep more of the good stuff for itself," he says.

With the Chinese tightening their grip and a general uptick in demand, prices have soared to about $20 a pound, double from a few years ago. That has the relatively small number of tungsten miners, such as Malaga and Woulfe Mining, ramping up activity. Malaga is currently sending one container, which is about 28,000 pounds, of tungsten per week from its Pasto Bueno mine in Peru, according to CEO Pierre Monet. To meet the pressure for more material, he says the mine would have to up its production to five containers per day.

Other mining companies such as Woulfe are capitalizing upon mines that shut down in past years when prices were a lot lower. In 2009, Woulfe acquired a one-time leading tungsten producer, South Korea's Sangdong mine, years after it had closed in 1992. Now the company is in a race to bring Sangdong back online while prices stay high. Woulfe hopes to have the mine in production by the first quarter of next year, says CEO Brian Wesson. But the company, like the rest of its sector, has been in a fight to get the capital it needs to fund the project.

Though tungsten use is spread across a wide range of industries, the quantities involved are still relatively small. There's been little historical interest in the U.S., and few mining analysts cover the material. (Malaga and Woulfe are both based in Canada.) According to Ecclestone at Hallgarten, the long lag time with mines from investment to production has kept investment interest in them relatively muted and their valuations low.

But that could change if executives are right in predicting that tungsten prices stay at high levels for the long haul. The U.S. is paying more attention to strategic metals and recently sued the Chinese government for its export restrictions of "rare earth" minerals, And now Warren Buffett is getting in on the act.

IMC Group, a subsidiary of Buffett's Berkshire Hathaway (BRKA) that holds a diverse portfolio of metalworking companies, recently invested $70 million in Woulfe's South Korean tungsten operations. Half that money goes to the mine itself, with the rest helping to finance a nearby plant for processing the raw material, Woulfe CEO Wesson says. The processed tungsten will then be used by units within IMC.

Mining for a partner

The historical model has been for a mining company to have one project in a given rare metal, with diversification coming from other mines of different minerals. Woulfe, for example, also owns a gold mine, the Maguk project, in South Korea. But Ecclestone says he would not be surprised to see consolidation among tungsten producers. "There are 15 players in the space each with one project, and there should be seven with two projects each." Malaga CEO Monet also notes that there is a limited pool of experienced mining experts capable of starting a new mine from scratch.

Any merger and acquisition activity, however, returns to the question of capital, and the industry can only hope that Berkshire Hathaway proves ahead of the curve in opening up funding. The success of the venture, however, will ultimately depend on the price of tungsten in the months after Sangdong goes operational. Ecclestone says his analysis shows little reason to believe prices will "go bad" anytime soon. But China poses potential headaches for Woulfe and IMC if it tries to manipulate the price.

"As a competitor to China, you're in the cage with the 800-pound gorilla," Ecclestone warns. But it's a cage match that Berkshire Hathaway has bet it can win. Tungsten futures, anyone?

A shorter version of this story appeared in the April 9, 2012 issue of Fortune.

Posted in: Berkshire Hathaway, metals, mines, mining, tungsten, Warren Buffett

Hanns CEO/Chinatungten.com

China V.S. The World, the Reason is Tungsten and Rare Earth

China V.S. The World, the Reason is Tungsten and Rare Earth

---England Challenges China by Reviving Strategic Mine: Commodities

An English mine last used to make armaments to defeat Hitler’s forces will be revived to challenge China’s grip on tungsten, among strategic metals at the heart of a deepening trade dispute with Europe and the U.S.

Wolf Minerals Ltd. (WLF) is developing a tungsten mine in Devon, southwest England, 70 years after it was last extracted there. The Hemerdon site is the world’s fourth-largest deposit and can produce about 3.5 percent of global demand for the metal, used to harden steel in ballistic missiles and in drill bits. China provides about 85 percent of worldwide supplies.

Tungsten was one of the metals cited when U.S. President Barack Obama filed a complaint to the World Trade Organization on March 13 against Chinese supply curbs. Tungsten is a “critical” raw material, according to the European Union, and the British Geological Survey places it at the top of its supply-risk list of materials needed to maintain the U.K.’s economy and lifestyle.

“A big element of what we are doing is providing a strategic supply to companies outside of China,” Wolf Managing Director Humphrey Hale said in an interview in London. “We’re answering a requirement from the market, which is strategic supply, and prices are at a position where we can make money from that.”

Wolf is backed by Resource Capital Funds, which holds a 17 percent stake, and Traxys SA, with 9.6 percent, data compiled by Bloomberg show. Resource Capital is the largest shareholder in Molycorp Inc. (MCP), owner of the biggest U.S. rare-earth deposit. Traxys, the Luxembourg-based metals trader, also owns a stake in Molycorp.

Tungsten Prices

China has imposed export restraints on raw materials including rare earths, tungsten and molybdenum, causing worldwide supplies to plummet, sending prices higher and threatening strategic stockpiles. China is the largest supplier of 28 of the 52 elements on the Geological Survey’s risk list.

Rare earths became a political and legislative flashpoint in July 2010 when China moved to limit domestic output and slash export quotas by 40 percent, souring ties with the U.S. and Japan, where buyers cut usage after prices soared in the first half of 2011. China said on Dec. 28 it was leaving overseas sales caps for 2012 virtually unchanged.

Tungsten prices will probably stay at more than $40,000 a metric ton this year because of China’s curbs, Malaga Inc. (MLG), a producer of the metal in Peru, said in January. The price of ammonium paratungstate, the traded form of the metal, increased 32 percent in 2011 to end the year at more than $440 a metric ton, according to European price data from Metal Bulletin (MBWOEUFM). The material traded at less than $65 a ton in 2003.

Key Commodity

“Investors should really look at Tungsten,” John Meyer, an analyst at Fairfax IS Plc, said in an interview with Maryam Nemazee on Bloomberg Television’s “The Pulse” on March 28. “Demand is so far ahead of supply, I think it’s the key commodity, a strategic commodity.”

Wolf shares have fallen 21 percent in the past year, compared with the 25 percent drop in the 25-member FTSE 350 Mining Index.

Wolf’s mine will produce 3,500 tons of tungsten and 450 tons of tin a year, starting in 2015. It will cost about 120 million pounds ($190 million) to build. Wolf has raised some 55 million pounds and is in talks for an additional 15 million to 20 million pounds in a sales agreement. The balance will be sought through selling shares, Hale said.

The Devon mine, which provided material used in both World Wars, was closed in 1944 as access to overseas supplies resumed. Wolf isn’t the first company to attempt to revive it.

North American Tungsten

Amax Inc. started efforts to develop the mine in the 1970s and was granted approval for the project from Devon’s local government in 1986. Amax withdrew from the project in 1993 after falling commodity prices made progressing uneconomic.

North American Tungsten Corp. (NTC) bought Hemerdon in 1997, before disposing of the asset in 2003, discouraged by persistently low prices.

Cornwall and West Devon have been mined for more than 3,500 years, supplying the Roman Empire and materials for the U.K.’s industrial revolution, according to Unesco. By the early 19th century, the region provided two-thirds of the world’s copper and was home to about 2,000 tin mines.

Competition from Chile and Australia in the 1860s closed many of the copper mines, while the tin sites struggled to survive as increased production in Malaysia and Australia drove down prices. The region’s last tin mine, South Crofty, closed in 1998.

Francis Drake

Wolf’s mine is about 10 miles from the maritime city of Plymouth. Sir Francis Drake masterminded the defeat of the Spanish Armada in 1588 from the city and in 1620 the Pilgrims set sail for the New World from Plymouth aboard the Mayflower.

Against the backdrop of 2012 market constraints and higher prices, the mine is now an example of how Britain can provide its own security of supply, Hale said.

“The U.K. does have stuff that’s been overlooked for years,” he said. “The perception round the world is that the planning permissions will be hard, the opportunities will be small and you’ll be up against an army of green protesters. The reality is the other way round.

‘‘It’s a big resource, it’s not bijou, hobby, clotted cream and jam,” he said. “This is world class.”

To contact the reporter on this story: Thomas Biesheuvel in London at tbiesheuvel@bloomberg.net

Collected by Hanns CEO/Chinatungten.com

---England Challenges China by Reviving Strategic Mine: Commodities

An English mine last used to make armaments to defeat Hitler’s forces will be revived to challenge China’s grip on tungsten, among strategic metals at the heart of a deepening trade dispute with Europe and the U.S.

Wolf Minerals Ltd. (WLF) is developing a tungsten mine in Devon, southwest England, 70 years after it was last extracted there. The Hemerdon site is the world’s fourth-largest deposit and can produce about 3.5 percent of global demand for the metal, used to harden steel in ballistic missiles and in drill bits. China provides about 85 percent of worldwide supplies.

Tungsten was one of the metals cited when U.S. President Barack Obama filed a complaint to the World Trade Organization on March 13 against Chinese supply curbs. Tungsten is a “critical” raw material, according to the European Union, and the British Geological Survey places it at the top of its supply-risk list of materials needed to maintain the U.K.’s economy and lifestyle.

“A big element of what we are doing is providing a strategic supply to companies outside of China,” Wolf Managing Director Humphrey Hale said in an interview in London. “We’re answering a requirement from the market, which is strategic supply, and prices are at a position where we can make money from that.”

Wolf is backed by Resource Capital Funds, which holds a 17 percent stake, and Traxys SA, with 9.6 percent, data compiled by Bloomberg show. Resource Capital is the largest shareholder in Molycorp Inc. (MCP), owner of the biggest U.S. rare-earth deposit. Traxys, the Luxembourg-based metals trader, also owns a stake in Molycorp.

Tungsten Prices

China has imposed export restraints on raw materials including rare earths, tungsten and molybdenum, causing worldwide supplies to plummet, sending prices higher and threatening strategic stockpiles. China is the largest supplier of 28 of the 52 elements on the Geological Survey’s risk list.

Rare earths became a political and legislative flashpoint in July 2010 when China moved to limit domestic output and slash export quotas by 40 percent, souring ties with the U.S. and Japan, where buyers cut usage after prices soared in the first half of 2011. China said on Dec. 28 it was leaving overseas sales caps for 2012 virtually unchanged.

Tungsten prices will probably stay at more than $40,000 a metric ton this year because of China’s curbs, Malaga Inc. (MLG), a producer of the metal in Peru, said in January. The price of ammonium paratungstate, the traded form of the metal, increased 32 percent in 2011 to end the year at more than $440 a metric ton, according to European price data from Metal Bulletin (MBWOEUFM). The material traded at less than $65 a ton in 2003.

Key Commodity

“Investors should really look at Tungsten,” John Meyer, an analyst at Fairfax IS Plc, said in an interview with Maryam Nemazee on Bloomberg Television’s “The Pulse” on March 28. “Demand is so far ahead of supply, I think it’s the key commodity, a strategic commodity.”

Wolf shares have fallen 21 percent in the past year, compared with the 25 percent drop in the 25-member FTSE 350 Mining Index.

Wolf’s mine will produce 3,500 tons of tungsten and 450 tons of tin a year, starting in 2015. It will cost about 120 million pounds ($190 million) to build. Wolf has raised some 55 million pounds and is in talks for an additional 15 million to 20 million pounds in a sales agreement. The balance will be sought through selling shares, Hale said.

The Devon mine, which provided material used in both World Wars, was closed in 1944 as access to overseas supplies resumed. Wolf isn’t the first company to attempt to revive it.

North American Tungsten

Amax Inc. started efforts to develop the mine in the 1970s and was granted approval for the project from Devon’s local government in 1986. Amax withdrew from the project in 1993 after falling commodity prices made progressing uneconomic.

North American Tungsten Corp. (NTC) bought Hemerdon in 1997, before disposing of the asset in 2003, discouraged by persistently low prices.

Cornwall and West Devon have been mined for more than 3,500 years, supplying the Roman Empire and materials for the U.K.’s industrial revolution, according to Unesco. By the early 19th century, the region provided two-thirds of the world’s copper and was home to about 2,000 tin mines.

Competition from Chile and Australia in the 1860s closed many of the copper mines, while the tin sites struggled to survive as increased production in Malaysia and Australia drove down prices. The region’s last tin mine, South Crofty, closed in 1998.

Francis Drake

Wolf’s mine is about 10 miles from the maritime city of Plymouth. Sir Francis Drake masterminded the defeat of the Spanish Armada in 1588 from the city and in 1620 the Pilgrims set sail for the New World from Plymouth aboard the Mayflower.

Against the backdrop of 2012 market constraints and higher prices, the mine is now an example of how Britain can provide its own security of supply, Hale said.

“The U.K. does have stuff that’s been overlooked for years,” he said. “The perception round the world is that the planning permissions will be hard, the opportunities will be small and you’ll be up against an army of green protesters. The reality is the other way round.

‘‘It’s a big resource, it’s not bijou, hobby, clotted cream and jam,” he said. “This is world class.”

To contact the reporter on this story: Thomas Biesheuvel in London at tbiesheuvel@bloomberg.net

Collected by Hanns CEO/Chinatungten.com

Who's Wrong? Tungsten or Tungsten Business Man?

Who's Wrong? Tungsten or Tungsten Business Man?---the Battle of Tungsten and Gold

Too many person have been talking about tungsten fake gold ba and or tungsten alloy gold bar in the past years, It seems that as an element tungsten should not be found on this earth, just because of the density of tungsten is almost same sa gold, and some person make it looks like gold bars. And it also seemd that China has done something wrong just because it has the most tungsten resourse in the world. it's realy unfair!

Anyone who may interested in tungsten, gold, tungsten alloy, tungsten carbide and the difference of them, please conttact me, I would like to let it know how's the tungsten is and what is the difference between tungsten alloy and gold.

How Much You Know About Tungsten

How Much You Know About Tungsten

------Brief Introduction of Tungsten

When and Who find Tungsten?

In 1779 Peter Woulfe deduced the existence of a new element - Tungsten - from his analysis of the mineral wolframite (an iron manganese tungstate mineral).

Tungsten was isolated as tungstic oxide (WO3) in 1781 by Carl W. Scheele from the mineral scheelite (calcium tungstate). However he did not have a suitable furnace to reduce the oxide to the metal.

Tungsten was finally isolated by Fausto and Juan Jose de Elhuyar in 1783 by reduction acidified wolframite with charcoal.en and The element name comes from the Swedish words 'tung sten', meaning heavy stone.

The chemical symbol, W, comes from the original name of the element, Wolfram.

Classification: Tungsten is a transition metal

Color: silvery-white

Atomic weight: 183.84

State: solid

Melting point: 3422 oC, 3695 K

Boiling point: 5550 oC, 5823 K

Shells: 2,8,18,32,12,2

Electron configuration: [Xe] 4f14 5d4 6s2

Density @ 20oC: 19.3 g/cm3

Atomic volume: 9.53 cm3/mol

Structure: bcc: body-centered cubic

Hardness: 7.5 mohs

Harmful effects:

Tungsten is considered to be of low toxicity.

Characteristics:

Tungsten is a very hard, dense, silvery-white, lustrous metal that tarnishes in air, forming a protective oxide coating. In powder form tungsten is gray in color.

The metal has the highest melting point of all metals, and at temperatures over 1650 oC also has the highest tensile strength. Pure tungsten is ductile, and tungsten wires, even of a very small diameter, have a very high tensile strength.

Tungsten is highly resistant to corrosion. It forms tungstic acid (H2WO4), or wolframic acid from the hydrated oxide (WO3) and its salts are called tungstates, or wolframates.

Tungsten is one of the five major refractory metals (metals with very high resistance to heat and wear). The other refactory metals are molybdenum, tantalum, rhenium and niobium.

Tungsten is considered to be of low toxicity.

Characteristics:

Tungsten is a very hard, dense, silvery-white, lustrous metal that tarnishes in air, forming a protective oxide coating. In powder form tungsten is gray in color.

The metal has the highest melting point of all metals, and at temperatures over 1650 oC also has the highest tensile strength. Pure tungsten is ductile, and tungsten wires, even of a very small diameter, have a very high tensile strength.

Tungsten is highly resistant to corrosion. It forms tungstic acid (H2WO4), or wolframic acid from the hydrated oxide (WO3) and its salts are called tungstates, or wolframates.

Tungsten is one of the five major refractory metals (metals with very high resistance to heat and wear). The other refactory metals are molybdenum, tantalum, rhenium and niobium.

Applications or Uses of Tungsten

Tungsten and its alloys are widely used for filaments in older style (not energy saving) electric bulbs and electronic tubes. It is used for making heavy metal alloys because of its hardness. Tungsten is used for high-temperature applications such as welding.

High speed steel (which can cut material at higher speeds than carbon steel), contains up to 18% tungsten.

Tungsten carbide (WC or W2C) is extremely hard and is used to make drills. It is also used for jewelry because of its hardness and wear resistance.

Video of Tungsten

Picture of tungsten

http://www.chinatungsten.com/picture-bank/

The Large Area Telescope (LAT) explores cosmic rays by tracking the electrons and positrons they produce after striking layers of tungsten. Credit: NASA/Goddard Space Flight Center Conceptual Image Lab

Abundance earth's crust: 1.25 parts per million by weight, 0.1 parts per million by moles

Abundance earth's crust: 1.25 parts per million by weight, 0.1 parts per million by moles Abundance solar system: 4 parts per billion by weight, 30 part per trillion by moles

Cost, pure: $11 per 100g

Cost, bulk: $2.95 per 100g

Source: Tungsten is not found free in nature. The principal ores of tungsten are wolframite (an iron manganese tungstate) and scheelite (calcium tungstate, CaWO3). Comercially, the metal is obtained by reducing tungsten oxide with hydrogen or carbon.

Isotopes: Tungsten has 33 isotopes whose half-lives are known with mass numbers from 158 to 190. Of these, three are stable: 180W, 182W, and 186W.

Specific heat capacity: 0.13 J g-1 K-1

Heat of fusion: 35.40 kJ mol-1

1st ionization energy: 770 kJ mol-1

3rd ionization energy: kJ mol-1

Heat of fusion: 35.40 kJ mol-1

1st ionization energy: 770 kJ mol-1

3rd ionization energy: kJ mol-1

Heat of atomization: 860 kJ mol-1

Heat of vaporization : 824.0 kJ mol-1

2nd ionization energy: 1700 kJ mol-1

Electron affinity: 78.6 kJ mol-1

Heat of vaporization : 824.0 kJ mol-1

2nd ionization energy: 1700 kJ mol-1

Electron affinity: 78.6 kJ mol-1

Shells: 2,8,18,32,12,2

Minimum oxidation number: -2

Min. common oxidation no.: 0

Electronegativity (Pauling Scale): 2.36

Minimum oxidation number: -2

Min. common oxidation no.: 0

Electronegativity (Pauling Scale): 2.36

Electron configuration: [Xe] 4f14 5d4 6s2

Maximum oxidation number: 6

Max. common oxidation no.: 6

Polarizability volume: 11.1 Å3

Maximum oxidation number: 6

Max. common oxidation no.: 6

Polarizability volume: 11.1 Å3

Reaction with air: w/ht, ⇒ WO3

Reaction with 15 M HNO3: none

Oxide(s): WO2, WO3 (tungstic oxide)

Hydride(s):

Reaction with 15 M HNO3: none

Oxide(s): WO2, WO3 (tungstic oxide)

Hydride(s):

Reaction with 6 M HCl: none

Reaction with 6 M NaOH:

Chloride(s): WCl2, WCl4, WCl6

Reaction with 6 M NaOH:

Chloride(s): WCl2, WCl4, WCl6

Atomic radius: 139 pm

Ionic radius (2+ ion): pm

Ionic radius (2- ion): pm

Ionic radius (2+ ion): pm

Ionic radius (2- ion): pm

Ionic radius (1+ ion): pm

Ionic radius (3+ ion): pm

Ionic radius (1- ion): pm

Ionic radius (3+ ion): pm

Ionic radius (1- ion): pm

Thermal conductivity: 173 W m-1 K-1

Electrical conductivity: 18.2 x 106 S m-1

2012/04/03

Tungsten, Name History and uses

Tungsten is a steel-gray to tin-white metal. Tungsten has the highest melting point and lowest vapour pressure of all metals, and at temperatures over 1650°C has the highest tensile strength. The metal oxidises in air and must be protected at elevated temperatures. It has excellent corrosion resistance and is attacked only slightly by most mineral acids.

Tungsten used to be known as wolfram (from wolframite, said to be named from wolf rahm or spumi lupi, because the ore interfered with the smelting of tin and was supposed to devour the tin). The de Elhuyar brothers found an acid in wolframite in 1783 that they succeeded in reducing to the elemental metal with charcoal.

Tungsten was discovered by Fausto and Juan Jose de Elhuyar at 1783 in Spain. Origin of name: from the Swedish words "tung sten" meaning "heavy stone" (the origin of the symbol W is "wolfram ", named after the tungsten mineral wolframite).

The following uses for tungsten are gathered from a number of sources as well as from anecdotal comments. I'd be delighted to receive corrections as well as additional referenced uses (please use the feedback mechanism to add uses).

Hanns CEO/Chinatungten.com

Tungsten used to be known as wolfram (from wolframite, said to be named from wolf rahm or spumi lupi, because the ore interfered with the smelting of tin and was supposed to devour the tin). The de Elhuyar brothers found an acid in wolframite in 1783 that they succeeded in reducing to the elemental metal with charcoal.

Tungsten was discovered by Fausto and Juan Jose de Elhuyar at 1783 in Spain. Origin of name: from the Swedish words "tung sten" meaning "heavy stone" (the origin of the symbol W is "wolfram ", named after the tungsten mineral wolframite).

The following uses for tungsten are gathered from a number of sources as well as from anecdotal comments. I'd be delighted to receive corrections as well as additional referenced uses (please use the feedback mechanism to add uses).

- useful for glass-to-metal seals since the thermal expansion is about the same as borosilicate glass

- tungsten and its alloys are used extensively for filaments for electric lamps, electron and television tubes, and for metal evaporation work

- electrical contact points for car distributors

- X-ray targets

- windings and heating elements for electrical furnaces

- missile and high-temperature applications

- high-speed tool steels and many other alloys contain tungsten

- the carbide is important to the metal-working, mining, and petroleum industries

- calcium and magnesium tungstates are widely used in fluorescent lighting

- tungsten salts are used in the chemical and tanning industries

- tungsten disulphide is a dry, high-temperature lubricant, stable to 500°C

- tungsten bronzes and other tungsten compounds are used in paints

- TV tubes (electron tubes)

- X-ray targets

Hanns CEO/Chinatungten.com

2012/04/02

Tungsten carbide sintered Saw Tip and Groover Tip profiles

| Tungsten carbide sintered Saw Tip and Groover Tip profiles are used for both wood and metal cutting applications. Tungsten carbide sintered Saw Tip and Groover Tip profiles are produced using automated press tooling. Standard Kerf widths dimensions range from between 2.1mm and 8.0mm. Larger Saw Tip profiles and hand shaped tip profiles to customer specification are available upon request. Other products that can be made to order include:

| |

| |

Hanns CEO/Chinatungten.com

Solid Tungsten Carbide Wear Resistant Components and Hard Facings.

| Solid Tungsten Carbide Wear Resistant Components and Hard Facings. Solid Tungsten Carbide Wear Resistant Components and Hard Facings are such as solid and sleeved Rollers, Slippers, Slipper Ends, Cheek Plates, Curved & Flat Guide Rails, Wear Plates and Mould Liners. Solid Tungsten Carbide Wear Resistant Components and Hard Facings are such as wear resistant grade tungsten carbide grades for use on individual components and piece parts. Components can be supplied brazed, glued or mechanically retained on to steel backings. In-house grinding facilities including Wire Cut EDM mean that items can be supplied fully ground to customer drawing. | |

| |

Solid Tungsten Carbide Wear Resistant Components and Hard Facings are such as following items in either solid or sleeved Tungsten Carbide or in conjunction with brazed, glued or mechanically retained steel hubs and backings.

|

Hanns CEO/Chinatungten.com

Tungsten Carbide Products for Oil and Gas Industry

Tungsten Carbide products for use in a wide range of Oil and Gas Industry applications including:

Hanns CEO/Chinatungten.com

- Flow Trim and Seat components and assemblies

- Centrifuge Tile assemblies

- Valve and Gauge components

- Stabilizer Inserts

- Plungers

Hanns CEO/Chinatungten.com

The Application of Tungsten Carbide Components

Tungsten Carbide Components and sub-assemblies across many industry sectors, some of which are listed below.

Hanns CEO/Chinatungten.com

| General | - | Pressed & Hand Shaped Tips, Blanks & Blocks, As-Sintered & Ground Rod, Bushes & Sleeves |

| Wear Parts | - | Crusher & Scraper Tips, Bar Hammers, Impact & Wear Plates, Lifters & Liners, Plain Bearings |

| Saw Tips | - | Circular Saw & Groover Tips for Metal, Wood & Masonary Tips, Router and special profiled Cutting Tips and inserts for Drilling, Tunnelling & Mining |

| Oil & Gas | - | Choke Valves and Flow Trim Assemblies including Plugs, Cages and Seats, Plungers, Centrifuge Tiles, Wear Sleeves, Stabiliser Inserts, Guides & Seal Rings, Weights and Choke Beans |

| Brick & Roof Tiles | - | Mould Liners, Flat Rollers, Profiled Slippers & Rollers, Cheek & Roller End Plates, Wear Tracks & Guides |

| Tooling | - | Powder Compaction Tools, Metal Can Tooling, Centres, Boring Bars, Gun Drill Bushes, Steadies |

| Metal Forming | - | Hot and Cold Heading Die Inserts & Bushes, Swaging Blocks, Punches & Dies |

| Wire & Tube | - | Turks Head & Wire Flattening Rolls, Wire Drawing, Extrusion, Swaging & Shaving Dies, Nibs and Points, Tube Weld Rolls, Forming Dies, Floating Dies, Plugs & Bullets, Eyelets |

| Cutters & Knives | - | Paper and Tobacco Knives & Anvils Tipped Shearing Blades |

| Nozzles | - | Shot Blast, Special Venturi Nozzles & Lance Tips |

Hanns CEO/Chinatungten.com

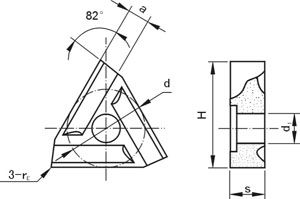

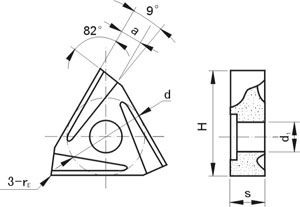

Tungsten Carbide Mechanically Clamped Inserts Type

Tungsten Carbide Mechanically Clamped Inserts Type 3C

Hanns CEO/Chinatungten.com

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

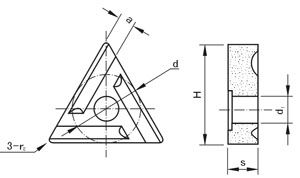

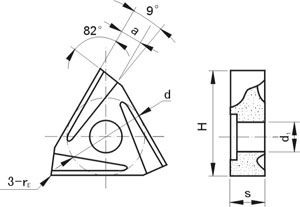

Tungsten Carbide Mechanically Clamped Inserts Type

Tungsten Carbide Mechanically Clamped Inserts Type 3D

Hanns CEO/Chinatungten.com

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tungsten Carbide Mechanically Clamped Inserts

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TUNGSTEN HISTORY, MINES AND PRODUCTS 1932-1933

Kiessling, O. E. / Minerals yearbook 1932-33

Year 1931-32 (1933)

Year 1931-32 (1933)

Hess, Frank L.

Tungsten , pp. 271-[280]

Tungsten , pp. 271-[280]

Hanns CEO/Chinatungten.com

Main Application of Tungsten

Main Application of Tungsten

Tungsten (W) is a metal with a wide range of uses, the largest of which is as tungsten carbide in cemented carbides. Cemented carbides (also called hardmetals) are wear-resistant materials used by the metalworking, mining, and construction industries. Tungsten metal wires, electrodes, and/or contacts are used in lighting, electronic, electrical, heating, and welding applications. Tungsten is also used to make heavy metal alloys for armaments, heat sinks, and high-density applications, such as weights and counterweights; superalloys for turbine blades; tool steels; and wear-resistant alloy parts and coatings. Tungsten composites are used as a substitute for lead in bullets and shot. Tungsten chemical compounds are used in catalysts, inorganic pigments, and high-temperature lubricants.

Hanns CEO/Chinatungten.com

Tungsten (W) is a metal with a wide range of uses, the largest of which is as tungsten carbide in cemented carbides. Cemented carbides (also called hardmetals) are wear-resistant materials used by the metalworking, mining, and construction industries. Tungsten metal wires, electrodes, and/or contacts are used in lighting, electronic, electrical, heating, and welding applications. Tungsten is also used to make heavy metal alloys for armaments, heat sinks, and high-density applications, such as weights and counterweights; superalloys for turbine blades; tool steels; and wear-resistant alloy parts and coatings. Tungsten composites are used as a substitute for lead in bullets and shot. Tungsten chemical compounds are used in catalysts, inorganic pigments, and high-temperature lubricants.

Hanns CEO/Chinatungten.com

2012/04/01

Tungsten Copper Alloys Pictures

Pictures Of Copper Tungsten Alloy

Copper Tungsten Alloy Contacts

Copper Tungsten Alloy Heat Sinks

Copper Tungsten Alloy Electrode Tips

Copper Tungsten Alloy Electrode Tips

Copper Tungsten Alloy Copper Tungsten Insert

For more pictures, please visit www.chinatungsten.com

Copper Tungsten Alloy Contacts

Copper Tungsten Alloy Heat Sinks

Copper Tungsten Alloy Electrode Tips

Copper Tungsten Alloy Electrode Tips

Copper Tungsten Alloy Copper Tungsten Insert

For more pictures, please visit www.chinatungsten.com

Tungsten Copper Alloys

Copper Tungsten Alloy(Cu-W alloy)plates, sheets and strips, rods,are always welded with copper and chrome-copper alloys ,as well as machined as required.

The Chemical Compnents and Physical Properties of tungsten copper alloys

Brand and NO. | Chemical Components % | Physical Properties | ||||||

Cu | Total Impurities ≤ | W | Density (g/cm³) ≥ | Hardness HB ≥ | Resistivity (µΩ·cm) ≤ | Conductivity IACS%≥ | Bending Strength Mpa≥ | |

CuW(50) | 50±2.0 | 0.5 | balance | 11.85 | 115 | 3.2 | 54 | |

CuW(55) | 45±2.0 | 0.5 | balance | 12.30 | 125 | 3.5 | 49 | |

CuW(60) | 40±2.0 | 0.5 | balance | 12.75 | 140 | 3.7 | 47 | |

CuW(65) | 35±2.0 | 0.5 | balance | 13.30 | 155 | 3.9 | 44 | |

CuW(70) | 30±2.0 | 0.5 | balance | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) | 25±2.0 | 0.5 | balance | 14.50 | 195 | 4.5 | 38 | 885 |

CuW(80) | 20±2.0 | 0.5 | balance | 15.15 | 220 | 5.0 | 34 | 980 |

CuW(85) | 15±2.0 | 0.5 | balance | 15.90 | 240 | 5.7 | 30 | 1080 |

CuW(90) | 10±2.0 | 0.5 | balance | 16.75 | 260 | 6.5 | 27 | |

High Density Tungsten Alloy Spheres

Based on tungsten,with the another elements such as Fe,Ni,Cu,Mn,Co, tungsten heavy alloy ighas a high density,high strength,wear and heat resistant.And it may used for instyumentati thons,medicale another element,militay and astronantic industries High-density Tungsten Alloys Product Physical Properties Notes:If customers have special requirements,we can negotiate concretelit y with each other.

2012/03/31

2012/03/27

Tungsten Carbides Powders

Tungsten Carbides Powders

Tungsten carbide powder applied to gate valves.Wear Resistant Thermal Spray Coatings of tungsten carbide are used for their hardness and wear resistance. When choosing a Tungsten Carbide Powder, the particle size and type of carbide selected are important in determining the correct material to combat various forms of erosion, abrasion and wear. Whereas the amount of metal matrix in the coating (nickel, cobalt, or alloy) will depend on the toughness and abrasion resistance required.

88 WC/ 12 Co

Good erosion, sliding and fretting wear resistance protection for applications under 1000F. Not for use in corrosive or impact applications. Used for machine parts, pump housing, fan blades, etc.

| Product | Detail |

| LA-3301 | -325 +15µ 89 WC / 11 Co |

| LA-3301-C | -270 +15µ 89 WC / 11 Co |

| Morphology | Sintered and Crushed |

| Method | Air Plasma Spray, HVOF |

| Equivalents | WC-106, Stellite JK-114 |

| Product | Detail |

| LA-3302 | -200 +325 88 WC / 12 Co |

| LA -3302-C | -100+200 88 WC/ 12 Co |

| Morphology | Sintered and Crushed |

| Method | Air Plasma Spray, HVOF |

| Equivalents | Sulzer Metco 71-NS, Diamalloy 2003, AMDRY 302 Tafa WC-104, Amperit 515.401 |

| Approvals | PWA 1302 |

| Product | Detail |

| LA-3072 | -325 + 5µ 88 WC / 12 Co |

| Morphology | Sintered and Crushed |

| Method | Air Plasma Spray, HVOF |

| Equivalents | Sulzer Metco 2004 |

| Product | Detail |

| -325 + 15µ 88 WC / 12 Co | |

| Morphology | Sintered and Crushed |

| Method | Air Plasma Spray, HVOF |

| Equivalents | Sulzer Metco 72SF-NS, AMDRY 927, Tafa WC-489-1, Stellite JK-112, Amperit 515.1, 515.400 |

| Approvals | AMS-7880 GE B50TF27-A/B |

| Product | Detail |

| LA-3372S | -270+15 88 WC / 12 Co |

| Morphology | Agglomerated and Sintered |

| Method | HVOF |

| Equivalents | Sulzer Metco HC Stark 514.074, JK 112, Amperit 514.074, Woka 3101 |

| Product | Detail |

| LA-3379 | -325+5, -270+15 89 WC/ 11 Co |

| Morphology | Sintered and Crushed |

| Specifications | PWA 1379 |

| Method | Air Plasma Spray, HVOF |

| Equivalents | Metco 71VF NS, Amdry 301, WC-106 |

| Approvals | PWA 1379 |

83 WC / 17 Co

Tungsten Carbide coatings have higher toughness, ductility and fretting resistance than coatings of 88/12. Appropriate for non-corrosive applications under 1000F.

| Product | Detail |

| LA-3073 | -325 +5µ 83 WC / 17 Co |

| Morphology | Sintered and Crushed |

| Method | Air Plasma Spray, HVOF |

| Equivalents | Amperit 525.1, Diamalloy 2005 |

| Product | Detail |

| LA-3373 | -270 +5µ 83 WC / 17 Co |

| Morphology | Sintered and Crushed |

| Equivalents | Metco 73F NS, WC 128 |

| Approvals | AMS 2447, Bell BPS 4463, Honeywell PS 1401 |

| Product | Detail |

| LA-3373S | -270 +15µ 83 WC / 17 Co |

| Morphology | Agglomerated and Sintered |

| Method | HVOF |

| Equivalents | Diamalloy 2004, Amdry 9830, Sulzer 73F, Woka 3201, 3206, TAFA 1343VF, JK 117, Amperit 526.062 |

80 WC / 20 Co

Appropriate for applications under 1000F. Recommended for gripping and traction applications that requiring a coarse coating.

| Product | Detail |

| LA-3374 | -270+5µ 80 WC/ 20 Co |

| Morphology | Sintered and Crushed |

| Method | Combustion |

| Equivalents | Metco 76F NS, Amdry 985 |

86 WC/ 10 Co/ 4 Cr

Appropriate for applications under 1000°F. CoCr matrix has higher abrasion and corrosion resistance than Co. Hard chrome replacement. Used on rolls, gate valves and seats, ball valves.

| Product | Detail |

| LA-3086 | -325+5µ 86 WC/10 Co/ 4Cr |

| Morphology | Sintered and Crushed |

| Method | Air Plasma Spray, HVOF |

| Equivalents | Amperit 554.074 |

| Product | Detail |

| -325+15µ 86 WC/10 Co/ 4Cr | |

| Morphology | Sintered and Crushed |

| Method | HVOF |

| Equivalents | Amdry 5843, WC-436-1, JK 120, Amperit 554.074 |

| Approvals | BOEING BMS 10-67K TYPE 17, MESSIER DOWTY PCS-2561, GOODRICH LGMS 9011-A BPS 4013 Type III Class B BPS 4013 Type III Class B |

| Product | Detail |

| -270+15µ 86 WC/10 Co/ 4 Cr | |

| Morphology | Sintered and Crushed |

| Method | HVOF |

| Product | Detail |

| -270+15µ 86 WC/10 Co/ 4Cr | |

| Morphology | Agglomerated and Sintered |

| Equivalents | Amdry 5847, 1350-VM, JK 120 |

90 WC/ 10 Ni

Appropriate for applications under 1000°F. Nickel matrix WC has higher corrosion resistance than Cobalt. Applications include ball valves and seats. Hard chrome replacement.

| Product | Detail |

| -325+15µ 90 WC/ 10 Ni | |

| Morphology | Sintered and crushed |

| Method | HVOF |

| Equivalents | 1310VM, JK-6189, mperit 547.074, Woka 3301 |

| Product | Detail |

| LA-3N10-S | -325+15u 90WC/10 Ni |

| Morphology | Agglomerated and Sintered |

| Method | HVOF |

| Equivalents | 1310VM, JK-6189, Amperit 547.074, Woka 3301 |

70 WC/ 20 Cr3C2/ 6 Ni

| Product | Detail |

| LA-3085 | -325+5µ 74 WC/ 20 Cr3C2 C2/ 6 Ni |

| Morphology | Sintered |

| Method | Air Plasma Spray, HVOF |

| Equivalent | WC-496, JK 125 |

| Coatings of LA 3085 are resistant to abrasion, solid particle erosion, cavitation and fretting wear up to about 1800F in addition to being resistant to sour gas. Applications include chrome replacement. | |

| Product | Detail |

| LA-3385 | -325+15µ 74 WC/ 20 Cr3C2 C2/ 6Ni |

| Morphology | Sintered |

| Method | HVOF |

| Equivalents | WC-496, JK 125 |

75 WCCo / Nickel Super Alloy Blend

| Product | Detail |

| LA-3303 | -325+11 WC/ 12 Co/ Ni Based Super Alloy |

| Method | HVOF |

| Equivalents | Metco 5803, Stelcar 6806 |

| Coatings of LA-3303 are excellent hard chrome replacement for applications under 1000°F. Resistant to cracking, fretting and abrasion. | |

Subscribe to:

Posts (Atom)

【Chinatungsten】tungsten copper electrolytic process

Processing In the process of electrolyzation, use a certain proportion of NaCl, KCl, Na2WO4 and CuO4 mixed solution and graphite as el...

-

Tungsten contact is used in the switch to connect or disconnect the circuit. Tungsten contact has a wide range of applications, covering a...

-

Yes, Tungsten Will be the Next Hot Rock! With demand for the metal on the rise, are investors like Berkshire Hathaway starting a "t...

-

Tungsten Carbides Powders Tungsten carbide powder applied to gate valves.Wear Resistant Thermal Spray Coatings of tungsten carbide are...